charpy impact test process|charpy impact cheat sheet : Big box store Unlock the essentials of the Izod / Charpy Impact Test with our in-depth guide. Learn about its definition, calculation methods, and why it’s crucial for material testing, aligning with ASTM standards, including ASTM D256 and .

WEB1 de abr. de 2021 · Genres Fantasy, Science Fiction, Comedy, Drama. Thirty-something Hazel Green tries to escape a suffocating marriage — until she realizes her tech .

{plog:ftitle_list}

ሐበሻ ስፖርት ውርርድ. @user-jn2oc7vm8t ‧ 1.64K subscribers ‧ 21 videos. The Official Habesha Sports Betting YouTube Channel. .

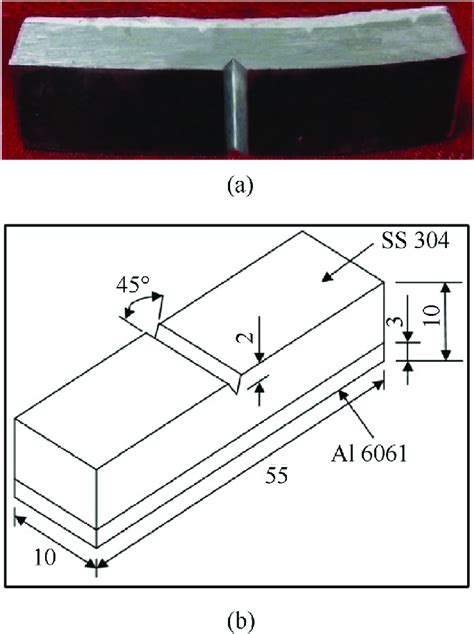

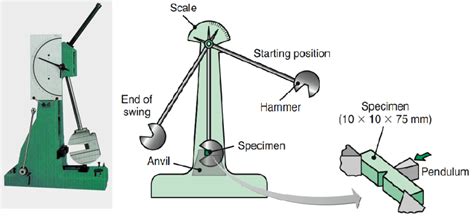

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the . Unlock the essentials of the Izod / Charpy Impact Test with our in-depth guide. Learn about its definition, calculation methods, and why it’s crucial for material testing, aligning with ASTM standards, including ASTM D256 and .

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. . Charpy Impact Testing: The .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . The set-up and process of Izod impact tests are identical to those of Charpy impact tests, .The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . i.e. if the material undergoes some process that makes it more brittle and less able to undergo plastic deformation. Such processes may .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, . The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for comparing the toughness of different metals but is more suited to providing information on the behavior of a single material at . The process of evaluating physical properties of the specimen is made easy using the NextGen Metallography equipment. . Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These .

A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. . “But impact is a highly dynamic process,” said NIST physicist Akobuije Chijioke, whose group has partnered with the .

charpy impact test specimen size

charpy impact test sample

A: The Charpy impact test was developed around 1900 and became known as the Charpy test after its inventor, Georges Charpy. It has since become a standard test method for evaluating material toughness. Q: What types of fractures can the Charpy impact tester evaluate? A: The Charpy impact test can evaluate both ductile and brittle fractures.The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good Quality Control (QC) method, and is globally accepted. . Schematic of a Typical Charpy Impact .

Charpy impact testing is used by investment casting foundries to determine whether an alloy can be classified as ductile or brittle. This information is important for assessing the quality and properties of a casting. In the Charpy impact testing method, a standard notched sample is struck with a specific weight pendulum raised to a predetermined [.]

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.At the heart of the Charpy test is the Charpy Impact Testing Machine. During the test, a pendulum arm is raised to a predetermined height and then released to strike the specimen with precision. . Quality Assurance: Quality assurance is a paramount consideration in any welding process. The Charpy test serves as a reliable and standardized .

FAQ: Charpy Impact Test: Understanding the Process and Results 1. What is the purpose of a Charpy impact test? The purpose of a Charpy impact test is to measure the amount of energy absorbed by a material when it is subjected to a sudden impact. This provides valuable information about the material's toughness and resistance to brittle fracture. The Testing Process. Understanding how a Charpy Impact Test works requires familiarity with its testing process: 1. Preparing the Test Specimen: Before commencing any tests, it’s essential to prepare suitable . Aluminum alloy wheels are used worldwide in both the warmest and coldest temperatures. This study was conducted to investigate the impact resistance of aluminum alloy wheels produced by the low-pressure die casting process in real-life conditions. The V-notched Charpy impact test specimens were extracted from T6 heat-treated A356 aluminum alloy .

Machining the notch is the next step in preparing specimens for Charpy and Izod impact testing. During this process, a controlled stress concentration point is created on the specimen through precise notches. Types of Notches. V-Notch: Typically 2 mm deep with a 45° angle and a 0.25 mm radius at the base. To perform a Charpy impact test, the material to be tested must first be machined to a specific set of dimensions as determined by one of the national or international testing standards. The machined material is then fixtured into place. . During the machining process, a groove is machined on the backside of the specimen. This notch is .V-notch Charpy impact test has been widely used to qualify toughness of steels and welds (e.g., [5, 6]). In this work, instrumented Charpy tests of pre-charged steel specimens were conducted at ambient temperature using a pendulum machine with a capacity of 750 J. Two to three repetitive specimens were tested for each pre-charging condition.

Metallic materialsHobart Brothers explain the process behind the Charpy impact test, a key indicator of the toughness of weld metal. Charpy Weld Impact Test Overview. By: Hobart Brothers . Play video in modal window. Charpy Weld Impact Test Overview. Procedure for Charpy Impact Test Specimen Preparation: Prepare a sample with dimensions of 55 mm x 10 mm x 10 mm, featuring a 2 mm notch at the center.. Test Specimen: Elevate the simple pendulum to its initial position and verify the correct adjustment of the testing machine.; Begin by calibrating the Charpy machine -rotate the dial gauge to the maximum . This research employs the Taguchi method and analysis of variance (ANOVA) to investigate, analyze, and optimize the impact strength of tough polylactic acid (PLA) material produced through fused deposition modeling (FDM). This study explores the effect of key printing parameters—specifically, infill density, raster angle, layer height, and print speed—on Charpy .

The ASME Impact Test Requirement I4I Academy LLC article provides information about impact test requirement in pressure vessel design and construction. . then you need to carry out the test. I will explain the process for exemption in this article. . (or design) temperature, if it is proved by conducting Charpy V-notch Impact tests on .

The Testing Process. Understanding how a Charpy Impact Test works requires familiarity with its testing process: 1. Preparing the Test Specimen: Before commencing any tests, it’s essential to prepare suitable test specimens according to specific standards or requirements related to size, shape, notch geometry, and orientation. 2. Alignment .

charpy impact test procedure pdf

using the rockwell hardness test files

WEBDobrodošli na najbolji hrvatski sportski forum! Pravila korištenja Gorica bez straha protiv Dinama: 'Tražimo prolaz, već smo otišli neporaženi s Maksimira'

charpy impact test process|charpy impact cheat sheet